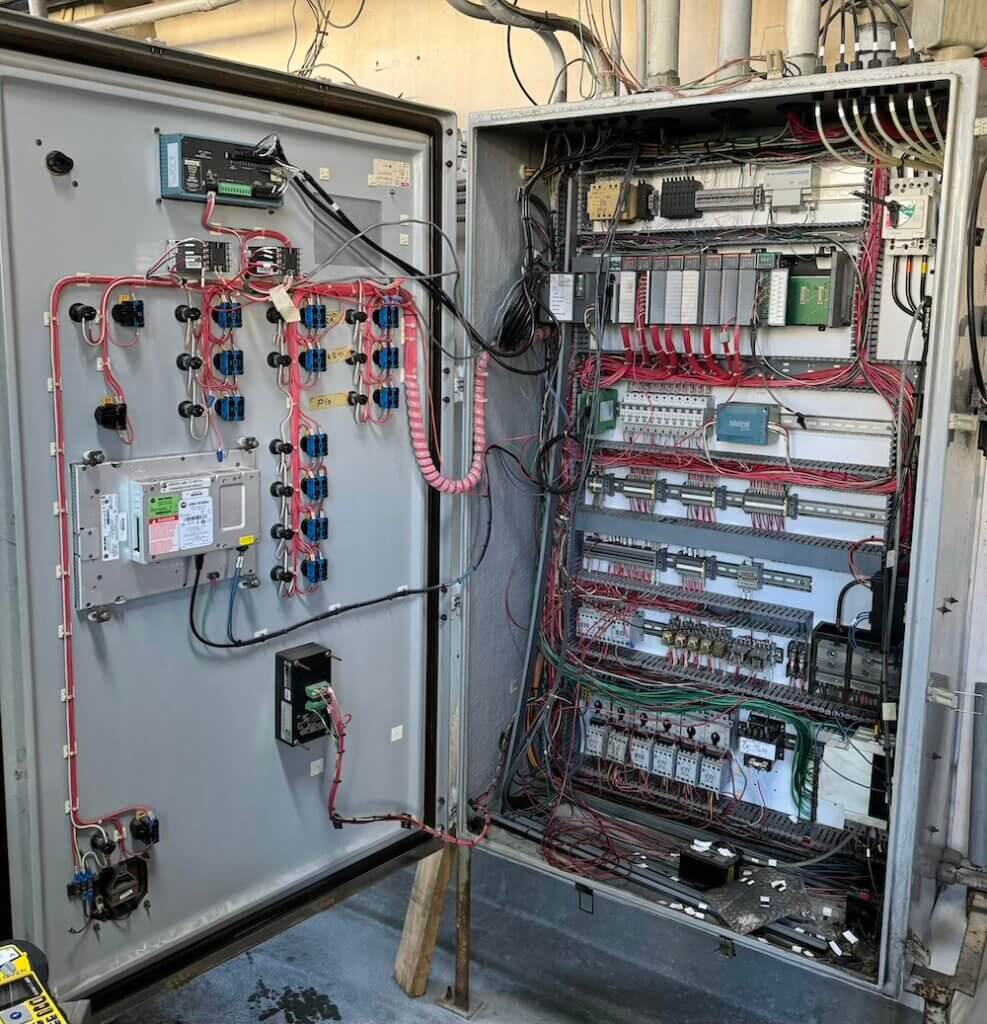

Original Water Filtration System Control Panel: SLC503 PLC, Panelview Plus HMI

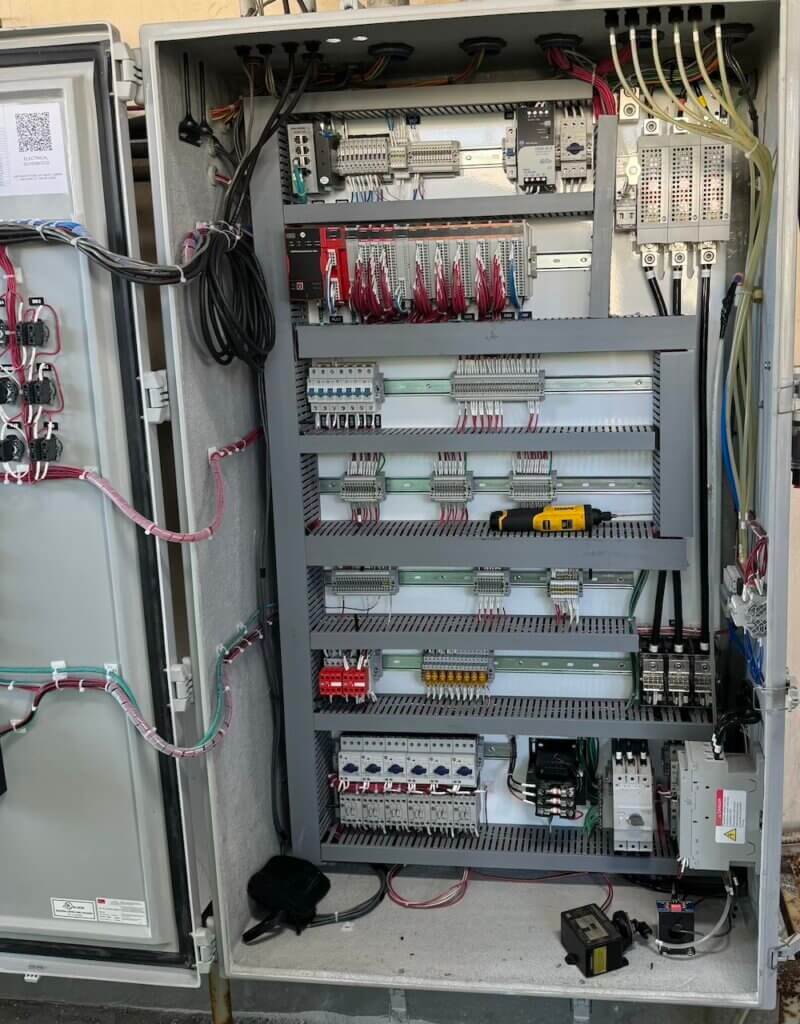

Upgrade Water Filtration System Control Panel: CompacLogix 5380 PLC, Panelview Plus 7 HMI

Managing wastewater from chemical plating is tough—heavy metals, oils, and strict regulations create challenges. Chemical plating wastewater filtration automation simplifies treatment, reduces costs, and ensures compliance. Here’s how automated systems transform wastewater management for plating facilities in five key ways.

Chemical plating produces wastewater with contaminants like nickel, zinc, and solvents that require advanced treatment to meet EPA standards. Automated filtration systems, like those from ALAR or PRAB, streamline processes, minimize labor, and enhance sustainability for electroplating and surface finishing operations.

The customer had an Allen-Bradley SLC503 PLC with a Panelview Plus. The PLC program did not have ASCII comments. The HMI program was corrupt, although running still (the tag database had an error during runtime to project conversion). There were no electrical drawings. Any moment, a component on this system could die, including the HMI or PLC, and the customer would be down for months, paying extensive engineering costs to replace it in an emergency and reprogramming from scratch. This was a ticking timebomb. Automation Ready Panels was able to help successfully get this system transitioned and running in just a couple of days because the customer was proactive in replacing this wastewater filtration controls system.

No Drawings: Used pictures taken onsite to retrace all wires and create new electrical prints. Ensured the component placement in the control panel matched the location in the new control panel.

HMI with Corrupt Tag Database: Used advanced Excel and XML tricks to recover 95% of the tag database. Converted this to a new Panelview Plus 7 HMI.

SLC PLC without ASCII Comments: Used the HMI tags to relabel the tags in the PLC. Converted this to a new 5069 CompactLogix PLC.

Process Sensor Settings: Once on site, record all settings in the current control panel process transmitters before powerdown.

Wiring Transfer: Ensuring all wiring have secured labels, take pictures before unlanding wires, and reland wires once the new panel was in place.

Replacing aging PLC Automation Panel Components and systems to prevent unscheduled downtime and a very expensive and time consuming repair. Ready to reduce risks to your operations? Visit our Advanced Automation Control Panel product web page. Learn more at Rockwell Automation’s 5380 CompactLogix Controllers website. Let Automation Ready Panels help with your next PLC upgrade automation project today! Contact Us

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We’ll Get Back To You Quickly!