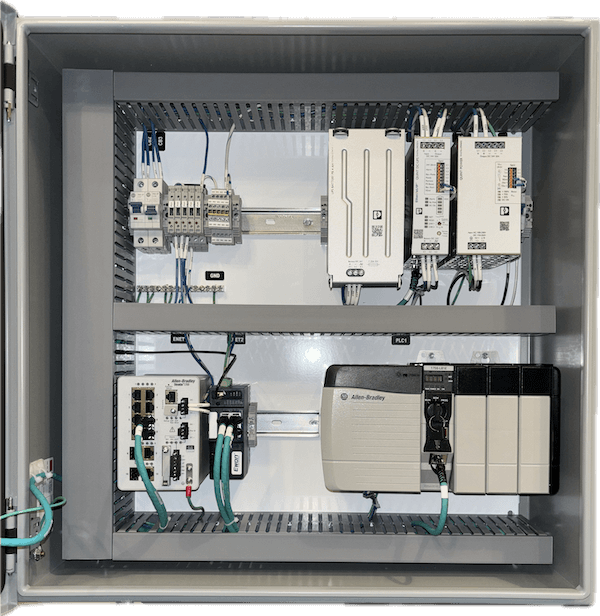

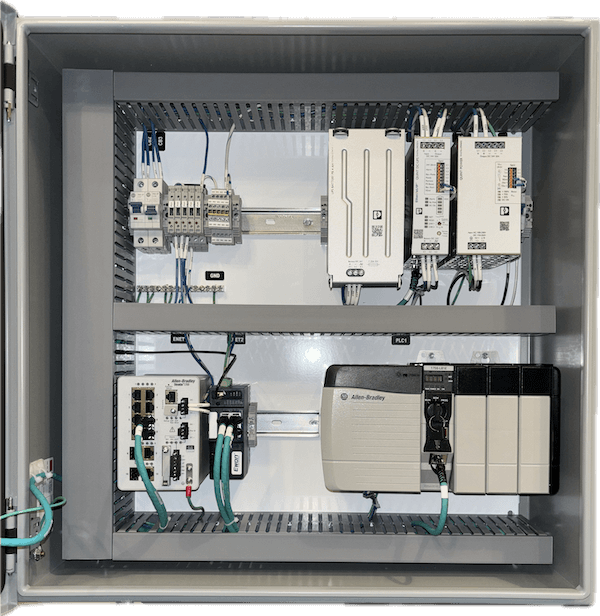

Ready for Enterprise Level Manufacturing Automation?

Managing large-scale industrial processes can be challenging. The ControlLogix PLC control panel from Allen-Bradley offers unmatched scalability, redundancy, and connectivity for high-performance automation. With support for EtherNet/IP and SIL 3 safety, it’s ideal for critical applications. Here are five key applications for the ControlLogix PLC in industrial automation.

Why Choose ControlLogix PLC Control Panels?

The ControlLogix 5580 series provide advanced processing, support for up to 128,000 I/O points, and integration with Studio 5000 Logix Designer. Built for reliability, they handle complex tasks in harsh environments like mining or chemical plants with redundancy and cybersecurity features.

Features That Processes or Machines Might Require That the ControlLogix 5580 Can Provide

The CompactLogix 5380 offers significant advancements over the Micro850’s mid-scale design, enabling larger, more integrated, and safety/motion-focused applications. Key differentiating features include:

- Redundancy and High Availability: Built-in controller redundancy (e.g., primary/secondary failover with no user programming needed) for zero-downtime in critical processes—essential for non-stop operations in oil/gas or utilities; CompactLogix lacks native redundancy.

- Scalability and Capacity: Up to 40 MB user memory (vs. 10 MB), 100 tasks (vs. 32), and 500 EtherNet/IP nodes/connections (vs. 180)—critical for plant-wide systems with massive I/O or data handling.

- Chassis-Based Architecture: Modular chassis (4-17 slots) with hot-swappable modules during operation, supporting larger backplanes and distributed I/O over longer distances—required for expansive factories; CompactLogix uses fixed or limited expansion without a traditional chassis.

- Performance and Processing: Faster execution (e.g., 0.12 ms/K for complex instructions) and higher throughput for large programs, with support for more Add-On Instructions and advanced diagnostics—vital for computation-heavy motion or process control.

- Motion and Integration: Enhanced support for up to 256 axes with advanced CIP Motion features, plus broader protocol compatibility (e.g., more robust DeviceNet or ControlNet options)—suited for synchronized, multi-controller setups.

- Environmental and Security: Wider temperature range in some models (-40 to 70°C) and advanced cybersecurity (e.g., deeper CIP Security implementation)—better for extreme or secure industrial environments.

- Other: Larger program capacity (e.g., 1000 programs per task) and seamless integration with legacy networks, enabling hybrid systems in brownfield upgrades.

7 ControlLogix 5580 PLC Control Panel Applications

Timing and Scheduling Applications

- Large-scale batch sequencing: Coordinating multi-stage operations in chemical plants or pharmaceutical production, using periodic tasks and CIP Sync for precise synchronization across controllers.

- Plant-wide scheduling systems: Managing shift operations or automated storage/retrieval in warehouses, with redundancy to ensure continuous uptime.

Level and Flow Control

- Industrial fluid processing skids: Advanced PID and high-resolution analog for regulating large tanks, pipelines, or mixing in oil/gas, wastewater treatment, or pulp/paper industries, supporting remote I/O over vast networks.

- High-volume chemical dosing or pumping stations: Flow control in refineries or water utilities, with diagnostics and redundancy for fault-tolerant operation.

Temperature and Environmental Control

- Industrial furnaces or kilns: Precise PID with thermocouple/RTD modules for heating in metals manufacturing or cement production, integrable with SCADA for enterprise monitoring.

- Facility-wide HVAC or climate systems: Multi-zone control in large factories or data centers, with conformal coating for harsh, corrosive environments.

Material Handling and Machines

- High-speed assembly lines or conveyors: Integrated motion for multi-axis robotics, indexing, or sorting in automotive or electronics manufacturing, using Kinetix drives for coordinated control.

- Complex packaging or bottling plants: Sequencing fillers, cappers, and palletizers in food/beverage lines, with high I/O density for sensor-heavy operations.

Monitoring and Sensing

- Heavy machinery diagnostics: Monitoring pressures, vibrations, or loads in mining equipment or compressors, with SNMP/HTTP for remote access and data logging via SD card.

- Production analytics in factories: Trend analysis and predictive maintenance for throughput in discrete manufacturing, handling massive data sets with large memory.

Safety-Critical Applications

- Presses or robotic workcells: SIL 3/PLe safety with GuardLogix for emergency stops and zone interlocking in automotive or heavy industry.

- Process safety in hazardous areas: Interlocking valves/pumps in oil/gas or chemical plants, sharing safety data across redundant controllers.

General Guidelines for Suitability

- Scale and Complexity: Best for systems with 4-17 chassis slots (expandable to thousands of I/O), up to 500 EtherNet/IP nodes, and redundancy needs; avoid for mid-size machines—use CompactLogix.

- Integration: Compatible with Kinetix drives, PanelView HMIs, remote I/O (e.g., FLEX 5000), and enterprise software; supports hot-swapping and -40 to 70°C operation.

- Environment: Suited for plant-wide, high-availability setups in process industries, discrete manufacturing, or utilities; common in upgrades from legacy systems for IIoT readiness.

Elevate Your Automation Today

The ControlLogix PLC control panel delivers scalable, secure control for complex industrial systems. Ready to expand your automation capabilities? Visit our ControlLogix Control Panel product web page. Learn more at Rockwell Automation’s ControlLogix Controllers and website. Let Automation Ready Panels help with your next ControlLogix automation project today! Contact Us

SHOP NOW