Traditional analog sensors limit visibility in industrial automation. IFM IO-Link sensors and AL1326 integration with CompactLogix unlock diagnostics, events, and process data. This setup outperforms standard analog sensors by providing real-time insights. Here’s how to set it up for superior monitoring.

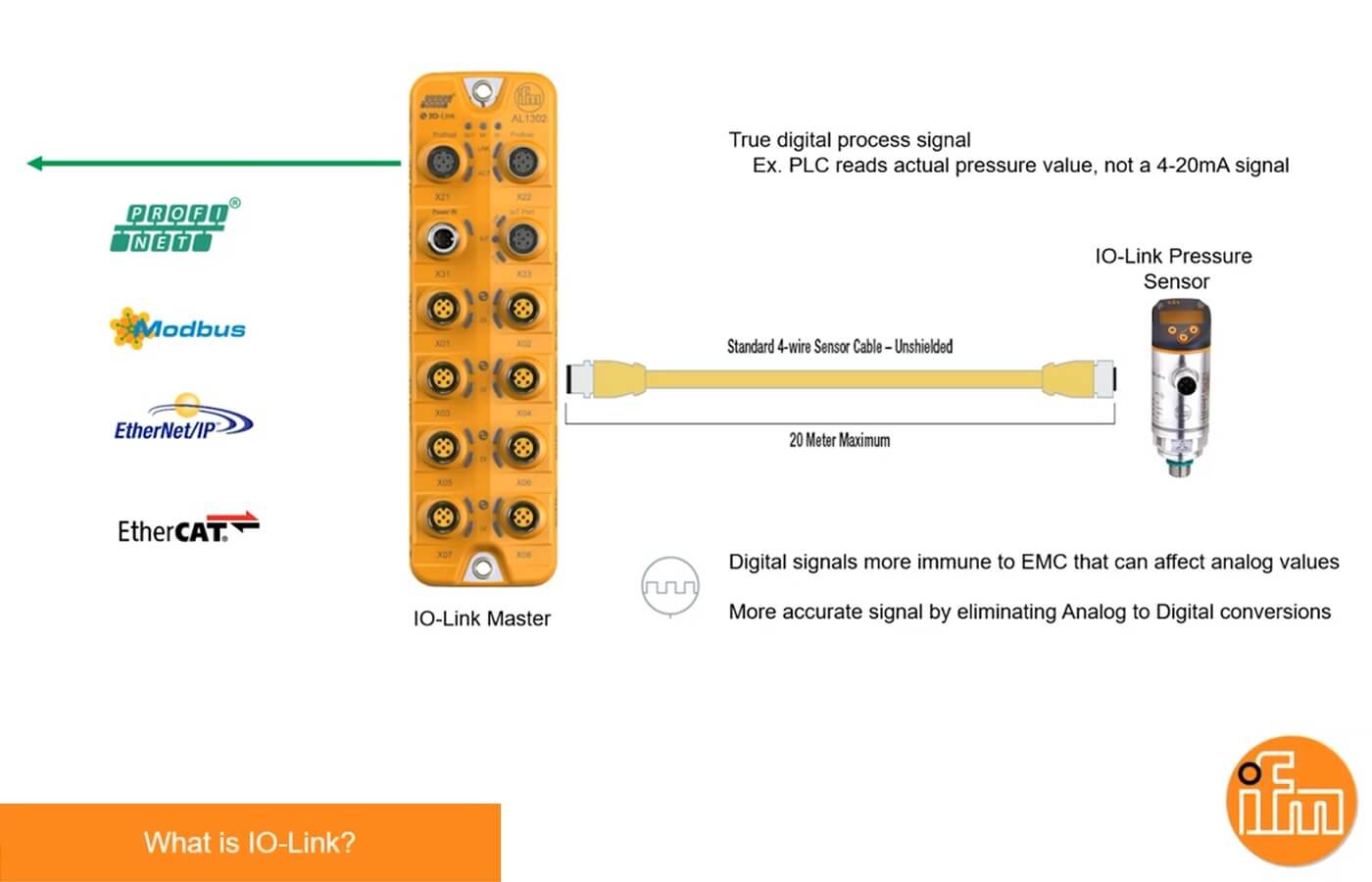

IFM IO-Link sensors transmit digital data over a single cable, offering cyclic (process) data, acyclic (parameters), and events (diagnostics). The AL1326 is an EtherNet/IP IO-Link master with 8 ports, robust for harsh environments, connecting up to eight devices. Compared to analog, IO-Link saves ~50% on input cards, eliminates scaling/noise issues, and adds valuable contextual data for using in the PLC logic.

Rich Data Access: View flow, temperature, diagnostics, and errors—beyond analog’s basic signals.

Cost Savings: No analog PLC cards needed, reducing hardware expenses.

Simplified Wiring: Digital communication over one cable minimizes noise and complexity.

Easy Maintenance: Remote parameterization and diagnostics cut downtime.

IIoT Integration: Enables seamless PLC and HMI connectivity for advanced monitoring.

The IFM SM8601 magnetic-inductive flow meter measures flow, consumption, and temperature with IO-Link. Unlike analog sensors, it provides:

Cyclic Data: Real-time volumetric flow (0.1–26.4 GPM), totalized volume, and media temperature.

Acyclic Data: Sensor parameters like calibration settings or flow direction for remote configuration.

Diagnostics: Device health, error codes (e.g., low flow), and event logs for predictive maintenance.

Outputs: Configurable switching, analog, or pulse signals via IO-Link for flexible control.

Connect Hardware: Wire SM8601 to AL1326 ports. Link AL1326 to CompactLogix via EtherNet/IP.

Studio 5000 Setup: Add AL1326 using AOP in Logix Designer. Map SM8601 data (flow, temperature) to tags.

HMI Configuration: In FactoryTalk View, create screens to display SM8601 data like flow rate or diagnostics from PLC tags.

Test Integration: Verify data flow; use acyclic commands to adjust SM8601 settings.

Monitor and Optimize: Use extended data for real-time control and maintenance.

IFM IO-Link sensors like SM8601 with AL1326 and CompactLogix deliver superior data visibility. Ready to upgrade? Learn more at IFM’s IO-Link Library website. Let Automation Ready Panels help with your next IFM IO-Link enhanced automation project today! Contact Us

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We’ll Get Back To You Quickly!