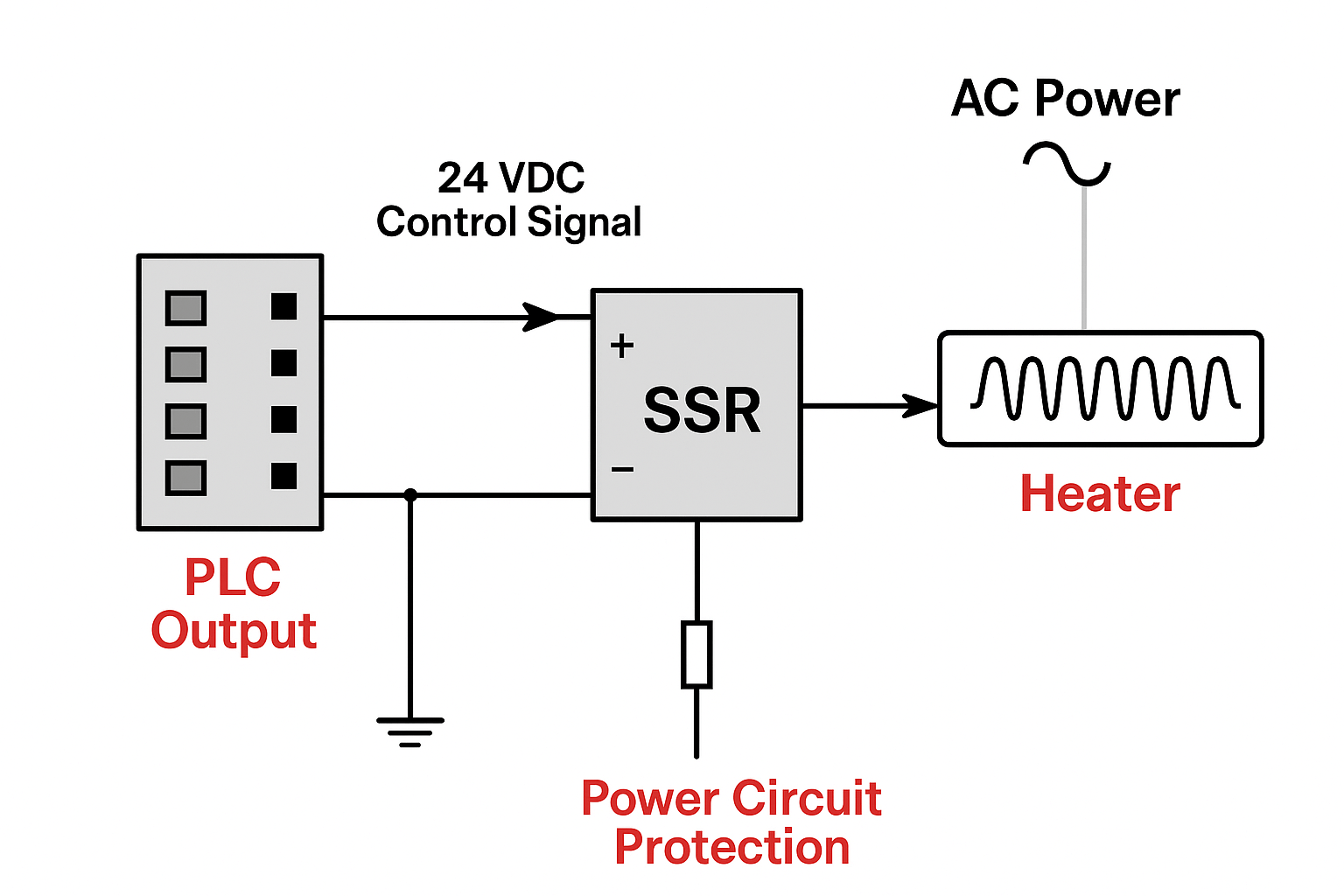

Controlling industrial heaters with a PLC and solid state relay (SSR) is a common and efficient way to regulate temperature. In this quick guide, we’ll explain the control signal required, the power circuit protection you need, and the differences between single-phase and three-phase heater applications.

Solid state relays are preferred for heater control because they:

Provide fast, precise switching for tight temperature regulation.

Have no moving parts, which increases reliability.

Can be controlled directly from a PLC output signal.

Most industrial SSRs used for heater control are designed to accept a DC control signal from a PLC, typically 24 VDC. The PLC energizes the SSR, which then switches the heater’s AC power on and off.

For applications requiring proportional control, some SSRs accept a 4–20 mA analog signal. This allows the PLC to modulate heater power instead of just switching it on/off, which is ideal for precise temperature loops controlled by a PID instruction in the PLC.

Proper protection ensures both safety and longevity of the heater circuit:

Single-Phase Heaters: Use a properly sized circuit breaker or fuse on the AC line side feeding the SSR. A fast-acting fuse is recommended to protect the SSR from short-circuit damage.

Three-Phase Heaters: Each phase should be protected with a fuse or breaker, and SSRs can be installed in one, two, or all three legs depending on the heater design. In most industrial applications, three SSRs (one per phase) are used for balanced control and safety.

Additionally, heat sinks or fan cooling may be required for SSRs since they generate heat during operation.

Single-Phase: Common in smaller process heaters, ovens, and lab equipment. Typically uses one SSR switching the hot leg, with a fuse for protection.

Three-Phase: Found in large industrial heaters, kilns, and process equipment. Requires either a 3-pole SSR assembly or three individual SSRs, each protected by fuses. The PLC can still provide the same 24 VDC or analog control signal to drive the system.

When using a PLC to control heaters with SSRs, the relay usually requires a 24 VDC control signal (or 4–20 mA for proportional control). Always size and install proper circuit protection—fast-acting fuses are strongly recommended. For single-phase heaters, one SSR is often sufficient, while three-phase systems typically require three SSRs with proper heat management.

👉 Need help designing a reliable heater control panel? Contact Automation Ready Panels today for expert PLC-based solutions.

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We’ll Get Back To You Quickly!