Need High-Performance Automation?

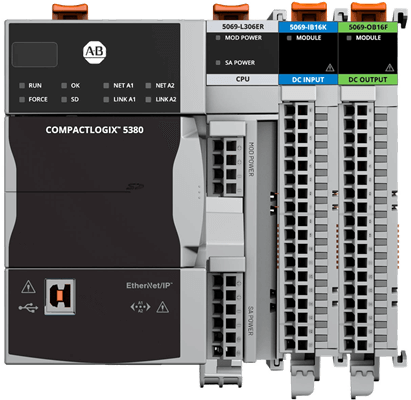

Struggling to manage complex automation tasks? The CompactLogix 5380 PLC control panel from Allen-Bradley delivers high performance, scalability, and security for smart machines. With support for up to 32 axes and EtherNet/IP, it’s ideal for demanding industries. Here are six key applications for the CompactLogix 5380 in industrial automation.

Why Choose CompactLogix 5380 PLC Control Panels?

The CompactLogix 5380 offers advanced processing, and Studio 5000 Logix Designer integration, making it perfect for high-speed motion, safety, and process control in industries like mining and oil & gas. Its compact design and flexible I/O suit mid-to-large applications.

Features That Processes or Machines Might Require That the CompactLogix 5380 Can Provide (But Micro850 Cannot)

The CompactLogix 5380 offers significant advancements over the Micro850’s mid-scale design, enabling larger, more integrated, and safety/motion-focused applications. Key differentiating features include:

- Scalability and Capacity: Up to 10 MB user memory (vs. Micro850’s ~160 KB max), 31 local I/O modules (vs. ~5 expansion slots), and 180 EtherNet/IP nodes (vs. ~60)—essential for expansive systems with high I/O density or remote devices.

- Communication and Networking: Dual 1 Gbps Ethernet ports with modes like Dual-IP (separate networks) and DLR (redundancy), CIP Security, SNMP, HTTP(S) REST API, and socket interfaces (TLS)—required for secure, enterprise-integrated setups or non-EtherNet/IP devices; Micro850 lacks dual ports and advanced protocols.

- Motion Control: Integrated support for up to 256 axes (CIP Drive, position loop) with Kinetix/PowerFlex drives and CIP Sync (IEEE-1588)—critical for synchronized robotics, indexing, or multi-axis machines; Micro850 has no built-in motion beyond basic PTO.

- Programming and Performance: Studio 5000 environment with 32 tasks (1000 programs/task), multiple languages (LD, ST, FBD, SFC), Add-On Instructions, and extended tag properties—vital for complex logic; faster scan times and no battery needed vs. Micro850’s simpler Connected Components Workbench.

- Safety Integration: Up to SIL 3/PLe (GuardLogix variants) with shared safety data and 1oo2 architecture—necessary for high-risk processes; Micro850 lacks certified safety.

- Process-Specific Features: Dedicated PlantPAx instructions and process-tasking models (e.g., 5069-L320ERP)—for plantwide control; conformal coating for harsh environments.

- Data Handling: SD card for logging/recipes (up to 32 GB), USB for programming, and diagnostics via webpages—suited for analytics-heavy apps.

- Environmental Robustness: Wider temp range (-20 to 70°C), IEC-62443 security certification—better for industrial extremes.

6 CompactLogix 5380 PLC Control Panel Applications

-

Temperature and Environmental Control

- Ovens, furnaces, or climate chambers: Advanced PID with thermocouple/RTD support for precise heating/cooling in manufacturing or labs, integrable with SCADA via EtherNet/IP.

- HVAC in industrial facilities: Multi-zone control with conformal-coated models for harsh environments like corrosive plants.

-

Material Handling and Machines

- High-performance indexing tables or conveyors: Integrated motion (up to 256 axes) with Kinetix drives for positioning in assembly lines or sorting systems.

- Packaging machines like case packers/erectors: Sequencing and motion control for fillers, sealers, or robotic arms in mid-scale production.

-

Monitoring and Sensing

- Pressure/vacuum systems in heavy machinery: High-density analog expansion and diagnostics for compressors or hydraulics, with SNMP for remote monitoring.

- Production analytics in factories: Data logging via SD card and trend analysis for throughput tracking, supporting up to 180 EtherNet/IP nodes.

-

Safety-Critical Applications

- Robotic cells or presses: SIL 3/PLe safety with GuardLogix variants for interlocking and emergency stops in automotive or pharma.

- Guarded process lines: Zone-to-zone safety data sharing for food/beverage or assembly.

-

Level and Flow Control

- Process skids for fluids: PID loops and high-resolution analog I/O for regulating levels in tanks or pipelines in water treatment, oil/gas, or pharmaceutical mixing, with PlantPAx instructions for process models.

- Chemical dosing or filling lines: Flow metering with remote I/O and Ethernet/IP for accurate control in batch processes.

-

Timing and Scheduling Applications

- Batch processing systems: Using real-time clock (RTC) and periodic tasks for sequenced operations in chemical or food production, with Ethernet for synchronized multi-controller setups.

- Automated warehouse scheduling: Coordinating gates, lifts, or shuttles with event-based tasks and CIP Sync for precise timing.

Transform Your Automation Today

The CompactLogix 5380 PLC control panel boosts efficiency, security, and scalability for advanced automation. Ready to expand your automation capabilities? Visit our CompactLogix Control Panel product web page. Learn more at Rockwell Automation’s CompactLogix Controllers and website. Let Automation Ready Panels help with your next CompactLogix automation project today! Contact Us

SHOP NOW