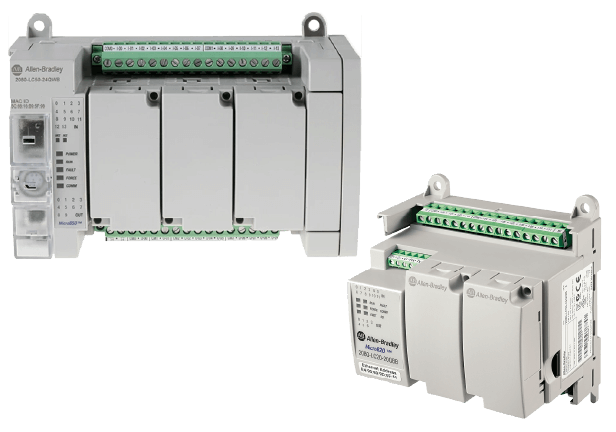

Looking for expandable control in larger standalone machines? The Micro820 and Micro850 PLC plcs from Allen-Bradley is ideal for mid-range automation tasks. With up to 48 I/O points, Ethernet connectivity, and motion capabilities, it excels in demanding environments. Here are five key applications for the Micro850 PLC in industrial automation.

The Allen-Bradley Micro820 PLC is a compact controller with a 20-point base, designed for smaller standalone machines and remote automation projects. It offers enhanced connectivity and flexibility compared to basic models, including embedded Ethernet and serial ports, microSD support for data logging and recipes, and limited plug-in expansion. It’s programmed via Connected Components Workbench and supports up to 35 I/O points with plug-ins, making it suitable for applications needing moderate I/O, communication, and basic motion (via PWM). It’s not ideal for large-scale or high-I/O systems but excels in cost-effective, networked setups with simple PID control and user-defined function blocks.

The Allen-Bradley Micro850 PLC is an expandable controller available in 24- or 48-point bases, targeted at larger standalone machine applications. It supports up to 192 I/O via expansion modules, embedded Ethernet and serial ports, motion control (up to 3 axes via PTO), high-performance analog I/O, and robust programming features like user-defined function blocks and PID. It’s ideal for mid-scale systems requiring flexible I/O, networking, and motion, but not for enterprise-level integration—consider CompactLogix for that.

Conveyor Systems: Automate material handling with high-speed counters and programmable limit switches for precise positioning and sorting.

PID Control Processes: Regulate temperature, pressure, or flow in systems like wastewater treatment using built-in PID function blocks with autotune.

Motion Control Machines: Control servo drives and stepper motors for robotic arms or CNC machines via pulse train outputs and motion function blocks.

Packaging Operations: Manage high-speed packaging lines with event interrupts and data logging for quality control and inventory tracking.

Batch Processes: Handle recipe management in chemical plating or food production with data sets for variable storage and loading.

The Micro820 and Micro850 PLC control panels deliver affordable, scalable control for small automation projects. Ready to streamline your operations? Visit our Micro820/850 Control Panel product web page. Learn more at Rockwell Automation’s Micro820 Controllers and Micro850 Controllers website. Let Automation Ready Panels help with your next Micro820 or Micro850 automation project today! Contact Us

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We’ll Get Back To You Quickly!