Confused about SIL safety automation ratings for your industrial systems? Safety Integrity Level (SIL) ratings, defined by IEC 61508, measure the reliability of safety functions in automation to reduce risks. From e-stops to PLCs like the 5069 GuardLogix, SIL ratings ensure compliance and safety. Here are five key points to understand SIL in automation.

SIL ratings (1 to 4) assess how well a safety system reduces risk, with SIL 3 common in industries like manufacturing and mining. Higher SIL levels mean lower failure probabilities, ensuring safer operations with components like Allen-Bradley’s GuardLogix PLCs.

SIL Level 1: SIL 1 offers basic risk reduction (PFD of 0.1–0.01 (or 10⁻¹ to 10⁻²) and a risk reduction factor (RRF) of 10–100). A basic emergency shutdown system in a chemical plant to handle moderate hazards like minor overpressure.

SIL Level 3: SIL 3 provides substantial risk reduction (PFD of 0.001–0.0001 (or 10⁻³ to 10⁻⁴) and RRF of 1000–10,000). A reactor overheating prevention system in a nuclear power plant to avoid severe accidents.

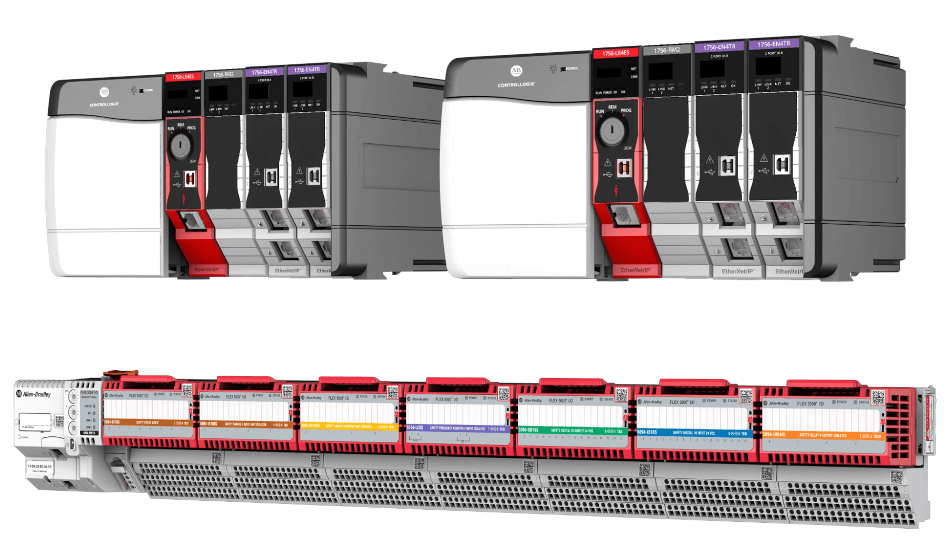

SIL Levels Explained: SIL 1 offers basic risk reduction, while SIL 3 (e.g., GuardLogix 5069) achieves a failure probability below 1.0 E-07 PFHd, ideal for high-risk processes like conveyors.

Component Integration: Use SIL-rated devices like Guardmaster light curtains or PowerFlex 525 VFDs with Safe Torque-Off (STO) to meet SIL 3 via CIP Safety over EtherNet/IP.

Verification Process: Validate SIL ratings using tools like SISTEMA. Ensure dual-channel inputs (e.g., 5069-IB8S for e-stops) and safety tasks in Studio 5000 for compliance.

Redundancy Requirements: SIL 2/3 requires redundant wiring and diagnostics. For example, 100S-C safety contactors provide feedback to GuardLogix for fault detection.

Certification Standards: Achieve SIL 3 with TÜV-certified components and testing. Follow IEC 61508 guidelines to document safety functions and performance.

Understanding SIL safety automation ratings ensures your systems meet stringent safety standards. Start implementing SIL-rated solutions with Allen-Bradley components today. Visit Rockwell Automation’s Safety Page for more details. Let Automation Ready Panels design and program your next PLC control system today! Contact Us

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We’ll Get Back To You Quickly!