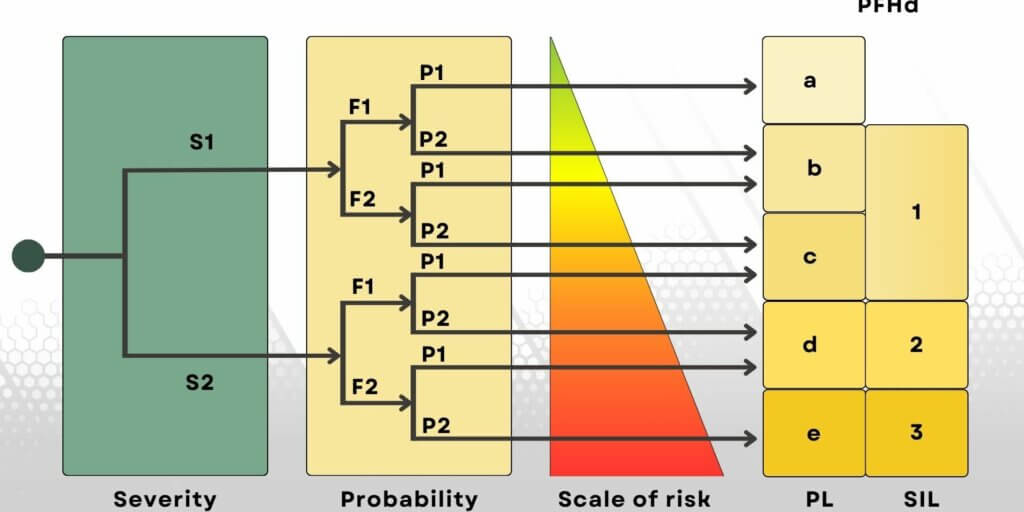

Navigating industrial safety standards? TÜV safety ratings performance levels certify machine control systems under ISO 13849-1, ensuring reliability against hazards. TÜV, a leading certification body, validates these Performance Levels (PL) from a to e, helping reduce risks in automation. Here are the five levels explained with real-world examples.

TÜV assesses PL based on failure probability, diagnostics, and redundancy, aligning with ISO 13849-1. Higher PL means better safety integrity, often required for TÜV-certified systems like Allen-Bradley GuardLogix PLCs in high-risk industries.

PLa (Lowest): High failure probability (≥10⁻⁵ PFHd). Example: A basic limit switch and contactor for a low-risk conveyor guard in packaging, where failure poses minimal harm.

PLb: Moderate reliability (≥3×10⁻⁶ PFHd). Example: Simple interlock switch on a low-speed drill press, ensuring basic guarding in workshops with limited exposure.

PLc: Improved diagnostics (≥10⁻⁶ PFHd). Example: Guard lock switch with safety relay and motor contactors on an assembly line machine, monitoring access to moderate hazards.

PLd: High integrity (≥10⁻⁷ PFHd). Example: Safety PLC like GuardLogix with interlocked guards on a robotic cell, preventing access during operation in manufacturing.

PLe (Highest): Lowest failure risk (≥10⁻⁸ PFHd). Example: Redundant safety relays and RFID interlocks on a high-speed press, ensuring fault-tolerant emergency stops in automotive production.

Understanding TÜV safety ratings performance levels ensures your systems meet global standards. Certify with TÜV for peace of mind. Visit TÜV Rheinland’s machinery safety page for more

details. Let Automation Ready Panels design and program your next PLC control system today! Contact Us

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We’ll Get Back To You Quickly!