Need to control several motors simultaneously with a single drive? PowerFlex 525 multiple motors control is possible for identical motors running at the same speed and direction, like in conveyors or fans. This setup saves costs but requires careful sizing and protection to meet NEC standards. Here’s what you need to know, including components, wire sizes, VFD sizing, overloads, and more.

The PowerFlex 525 supports multi-motor setups in V/Hz mode (not Vector), where motors share the load evenly. Individual overload protection is mandatory per NEC, as the VFD senses total load only. Add 20% to total FLA for VFD selection to account for harmonics and inefficiencies.

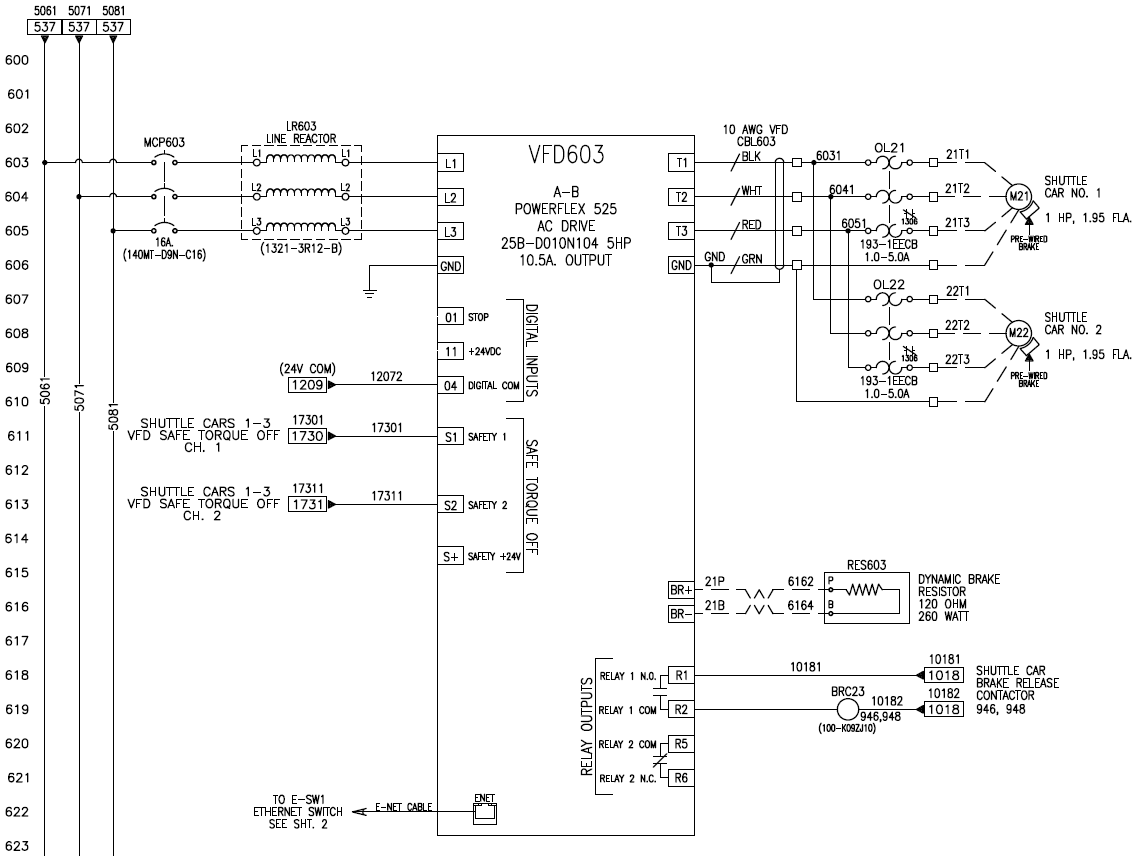

Components Required: PowerFlex 525 VFD, identical 3-phase motors, 140MT-D9V Motor Protection Circuit Breakers (MPCBs) for each motor (e.g., one per motor for overload/short-circuit protection), branch circuit protection like 140G Molded Case Circuit Breaker, optional contactors for isolation, and XLPE cables with common mode cores to reduce charging currents.

VFD Size: Sum all motor FLAs, add 20%, and select VFD rating accordingly (e.g., Normal Duty up to 62.1A at 240V 3-phase). Derate for single-phase input if applicable; avoid setups below 3 HP due to cable charging issues. Set parameters like P033 [Motor OL Current] to sum of FLAs, P037 [Motor NP Power] to total HP.

Overloads: Install individual MPCBs (e.g., 140MT-D9V) on VFD output for each motor to provide thermal overload and short-circuit protection. VFD’s internal overload protects the drive, not motors. Wire MPCB auxiliaries to VFD enable input for shutdown on trip.

Other Considerations: Use V/Hz control mode; PWM frequency ≤4 kHz, output ≤400 Hz. Motors start/stop together; monitor for speed variations due to slip. Test under load; comply with EMC and safety standards. Not ideal for uneven loads or precise control.

For four 0.75 kW (1 HP, 1.75A, 460V) motors on a conveyor: Sum FLA = 7A +20% = 8.4A; select PowerFlex 525 rated at least 11A (e.g., 25B-D010N104 for 5 HP ND). Wire with 10 AWG power lines, install four 140MT-D9V-B25 MPCBs set to 1.75A each. Parameters: P033=7A, P037=4 HP, V/Hz mode. This setup ensures protection and efficiency in mining or packaging applications.

Master PowerFlex 525 multiple motors control for cost-effective automation. Consider these guidelines for safe, reliable operation. Visit Rockwell Automation for more details. Let Automation Ready Panels design and program your next PLC control system today! Contact Us

In our last project, schedule and quality were very good.�? Also, the coordination and help during installation was good.

Metro Sewer District

David, Senior Electrical Engineer

As far as the internal wiring of the enclosures, I did not find a single wiring error.�? That is very impressive considering the number of enclosures we ordered. I want to thank everyone for the great work.

Brewing Company

Steve, Project Manager

I receieved excellent customer support, and quickly. Thank you so much!

Oil and Gas

John Herman, Controls Engineer

We needed a simple, easy-to-install chemical addition and mixing control system. Started up without an issue. Our operators seem pleased with the outcome!

Chemical Processing Plant

Jacob, Production Manager

We’ll Get Back To You Quickly!